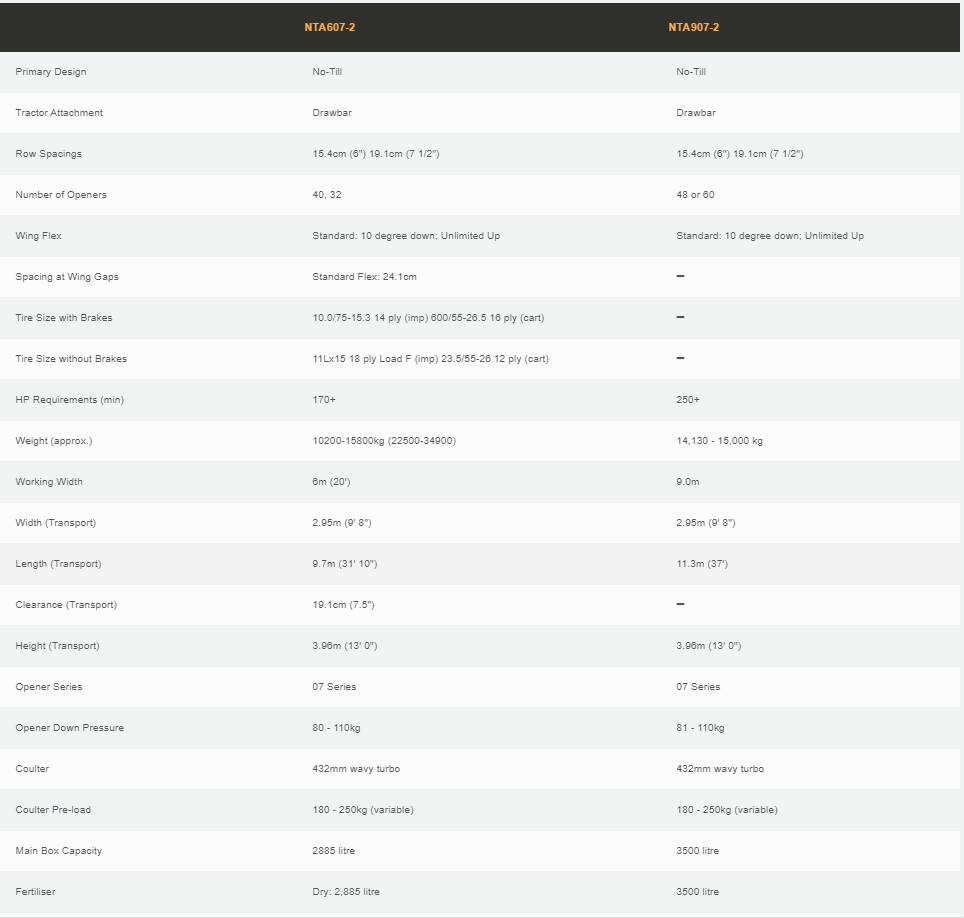

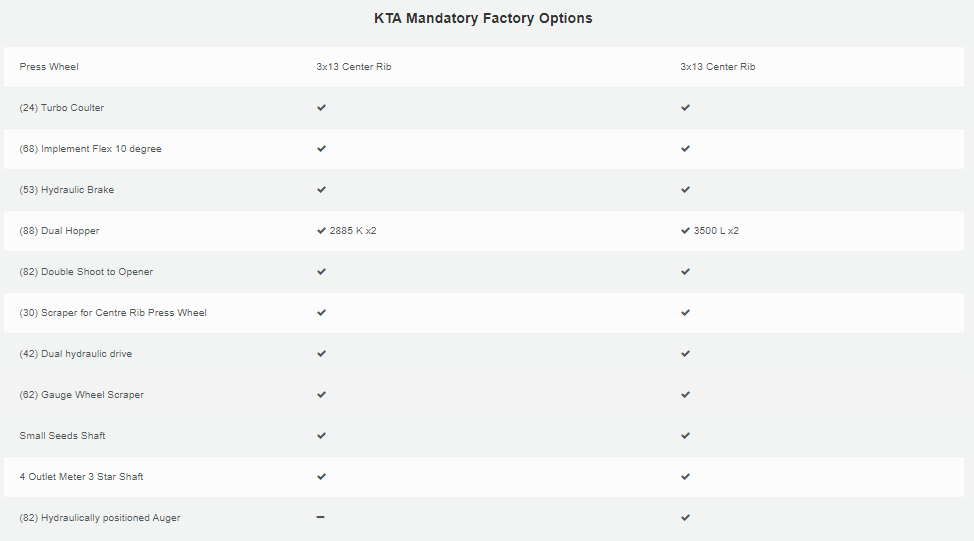

The SpartanII range is the next generation of Spartans incorporating new and improved features further increasing the productivity and versatility of this well-proven direct drilling solution. The second generation machine has been updated to suit Australian and New Zealand conditions.

Built around tried and tested components and technologies, such as the well-proven zone cultivation design of Great Plains’ 07 Series opener, the new Spartan incorporates a wide range of new and improved features.

Perhaps the most significant change to the Spartan is a complete rework of the drill’s seed tower configuration based on the design platform established with the company’s Centurion cultivator drill. The new patented system utilises half the number of towers and all of them are mounted on the center section.

Other improvements have been made with ease-of-use very much in mind, including seed calibration located at the rear of the machine, easier access to weight brackets, improved on-road handling and new variable-rate hydraulic drive.

The Spartan II retained many important features as well: zone cultivation seeding, impressive opener down-pressure for true no-till seeding, hydraulic weight transfer and excellent ground contour following. The Spartan II comes with two 2885 litre hoppers for seed/dry fertiliser applications. The new 6m working-width Spartan II 607 can be specified with 40 or 32 rows, giving row spacings of 15cm and 19cm respectively.

Seeding System = Zone Cultivation

This technology ensures that every seed sown is placed at the optimum depth in an ideal environment to facilitate consistently even germination and it is an integral part of the specification of our widely acclaimed and highly successful direct drills.

Patented Tower System

The tower system on the new Spartan II 607 has been completely redesigned. The new arrangement not only looks cleaner and tidier, but also offers some important practical benefits.

Precise Ground Contour Following

Wings of the frame can flex down 10 degrees and up over 15 degrees. The Spartan also features great flexibility of 15 degrees from front to back.

Hydraulic Drive

The second generation Spartans replace a mechanical variable-rate drive with a variable-rate hydraulic drive to allow population adjustments from the cab, as well as variable rate mapping.

Rear Casters

The rear axle on the new Spartan has a significantly increased track width to improve stability on the road. New style caster wheels are fitted with 10.0-75-15.3 BKT tyres, capable of running at the higher speeds that customers demand. The rear casters follow in the same footprint as the cart tires so as not to create additional tracks. Tires also include a scraper to keep them clean. The operator can manually lock them in place for safe and controlled backing on and off of trailers or lorries.

Weight Brackets

Weight brackets have been relocated to make them more accessible. The weight brackets provide the weight necessary to achieve up to 250kg pressure per row to penetrate in no-till establishment systems. Now, with unimpeded access, these weight blocks can be quickly and easily removed for min-till operations, to reduce compaction or to mitigate the creation of tire tracks in softer conditions.

User-friendly Seed Calibration

Seed calibration is a quick and convenient push-button operation from the rear of the machine.

Small Seed Crops

The Spartan also has capabilities to establish small seed crops. An optional small seeds roller is available for cover crop applications, oilseed rape, clovers and other small seeds.