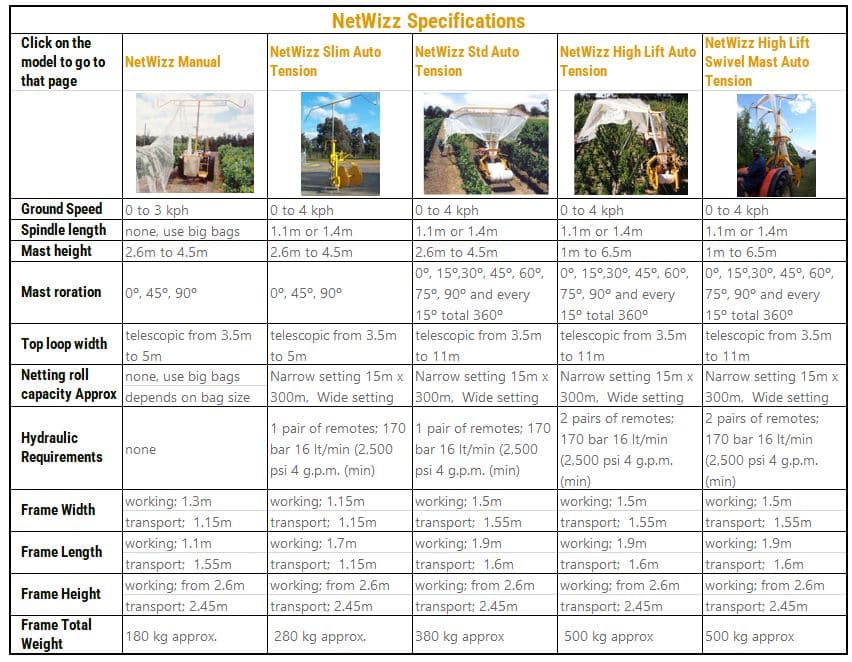

NetWizz Slim Auto Tension

“NetWizz Slim Auto Tension” is a machine for applying and removing bird netting in small vineyards, orchards and anywhere crop cover is required. Netting is wound onto a simple spindle in an inter-woven pattern like a roll of twine.

Key Benefits

- Automatic speed and netting tension

- Narrow width 1.1m

- Economically priced

- Fast, safe removal of netting without tears

- Netting wound tight on steel spindles

- For single and multiple row or full canopy cover netting

- Self-loading and unloading of netting rolls

- Shear pin protection for top loop & mast

- Very compact & safe design

- Improvements

- Larger netting eyes, handle bigger netting easier

- Stronger spindle covers

- Stronger frame & crank

- Easy v-belt adjustment

Specifications

Fast, safe removal of netting without tears

If netting gets caught the sensor automatically stops the spindle, preventing tears. The sensor automatically adjusts the spindle and wand speed to maintain a constant incoming net tension.

This unique sensor system greatly prolongs the life of netting.

Netting tension remains constant, no matter what size roll is being wound up or the tractor’s ground speed.

Telescopic mast & shear bolt protection for top loop & mast

The NetWizz mast incorporates a shear pin assembly which breaks, preventing the top loop and mast from damage.

To work around power poles, trees and for transport the top loop easily rotates 90º.

The mast is telescopic and is swung down to raise or lower and can be locked at four height settings.

Self loading and unloading of netting rolls

Full spindles are loaded using the tractor’s 3PL. The tractor is simply reversed into the roll, with the aid of a taper on the drive shaft, then raised with the linkage.

In the standard short setting 1.1m spindles, the roll of netting can be up to 15m wide x 300m long. In the long setting 1.4m spindles, the roll of netting can be up to 22m wide x 300m long.

The steel spindles protrude from the end of the roll enabling easy safe mechanical handling.

Automatic speed and netting tension

Netting tension is easily adjusted to suit different strength nets. Once the tension has been set to suit the netting there is no need to adjust it again.

All the tractor driver has to do is drive down the row and stop only if the netting becomes caught up on the vine trellis. No controls need to be adjusted while driving (retrieving or applying netting).

Netting wound tight on steel spindles

Netting is stored from the vine on square steel spindles and end covers are fitted when in use. These covers have high sides for easy operation.

The NetWizz comes with 3 spindles which are stored in the holder. These spindles are 50mm square x 1.6mm thick, being 1.1m long for standard setting and 1.4m for the long setting.

Net unrolling

When feeding out netting to cover the vines, a tapered drive pin is removed which allows the net to unroll.

For single and multiple row or full canopy cover netting

The NetWizz is a fully proven market leader. Safely handling different types and widths of netting, full canopy cover or over multiple and single rows .

Roll Spike (optional)

Efficient handling of netting rolls.

A roll spike is available, which is clamped to fork-lift or front-end loader forks and is then inserted into the spindle. This system allows rolls to be stacked on top of each other for safe and very compact storage. It is strongly recommended when handling large rolls of netting. (OPTIONAL EXTRA)