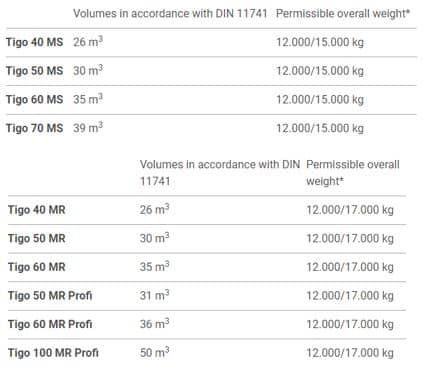

Fendt Tigo MS/MR/MR Profi Forage Wagons

Mastering those everyday tasks. Fendt Tigo MS.

The Fendt Tigo MS stands out from the crowd, especially when it comes to everyday tasks. The exceptionally gentle swing arm unit is especially suited to use in hay. Bringing in forage or loading silage each day also presents no problem for this all-rounder with a load capacity of up to 35 m³

Professional technology for your medium-sized business. Ultimate in feed quality. Vast loading space. Quick unloading. Look no further than the Fendt Tigo MR Profi forage wagon. Adding an extra 6 m³, the multifunctional bulkhead with VarioFill gives you an enormous loading space capacity of up to 50 m³. Whether silage or hay: The automatic loading system with continuously adjustable pre-compacting pressure uses every cubic metre and actively supports unloading. And the Tigo MR 100 Profi is a top-class hay loader – for the most demanding requirements.

The next level of harvesting technology – Fendt Tigo.

Fendt Tigo MS, MR and MR Profi.

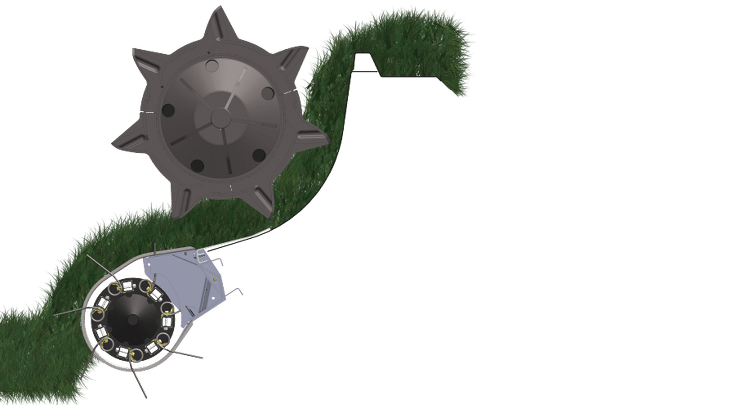

Preserve the sward with perfect ground following

The sensing roller protects the tines of the pick-up against piercing the ground through clear guidance. It maintains the appropriate ground clearance even in hard and uneven ground conditions and skates around the dirt. Smart technology means it supports you only when you need it, rather than being constantly there. You can individually set the sensing roller depending on the harvest conditions. Apart from optimum feed quality, the Fendt Tigo also takes care of soil protection. The adjustable, castor-steered gauge wheels support the pick-up and also protect the sward even when making tight turns in the field.

Clean work

A successful harvest all comes down to the best possible pick-up. The free-swinging pick-up adapts optimally to the ground. This not only makes it smoother to run and picks up the swath very cleanly, but also increases efficiency. During this process, the baffle plate with windguard applies even pressure on to the swath, and at the same time supports the conveyor effect of the pick-up. The interplay of the windguard and baffle plate reduces friction and ensures a continuous crop flow.

Long life

The Fendt Tigo pick-up does not require a cam track, which makes it absolutely maintenance-free and smooth running. To prevent damage to the machine or animals, all tines are secured against loss as standard. The structure, which features hot-dip galvanized components, protects the pick-up against wear caused by corrosive silage effluent, rust and weathering. The result is low maintenance and long service life.

Impressive performance

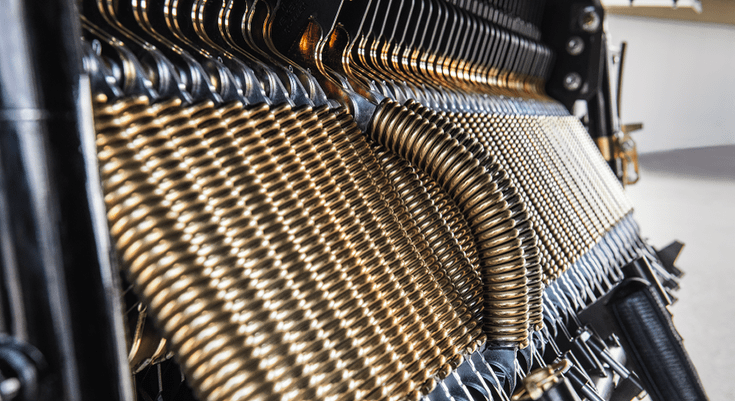

The rotor of the Fendt Tigo impresses with its strength and huge output. The 25 mm wide rotor tines with Hardox contact surfaces, makes the Fendt Tigo stand out from the crowd with its quality of cut. The grass is fed exactly through the narrow cutting gap and has no alternative way out. It is actively conveyed through the table while the six spiral rows of tines of the rotor provide for an efficient, precise cut. The rotor tines pull gently at an angle of more than 90 degrees out of the forage, which guarantees gentle discharge of the feed. With a feed channel of more than 1 m², the feed is carefully carried to the loading space even under difficult operating conditions. You thus achieve a precise quality of cut without crushing and optimum quality pre-compacted feed.

Knives

High-performance table

The better the quality of the cut, the better the compression, fermentation and forage digestion. The combination of 31 knives and a dragging cut together with a small cutting gap, guarantees a cleanly cut feed package without any mushy forage. The Fendt Tigo MR and MR Profi use elongated knives made of hardened tool steel with a special serrated edge. The wide rotor tines actively push the feed through the knives. This prolongs the service life of the Tigo and cuts along the entire length to produce the best quality silage. The necessary flexibility is provided by the easy cutting length adjustment. The tool lever can be used to effortlessly half the number of knives, and therefore to change the cutting length.

Easy maintenance

The aim is to make work as easy as possible for you. The rotor wagon ensures quick and easy handling through its knives which can be removed without the use of tools. Move the table bars from the operating to service position from the comfort of your terminal or by pressing the buttons on the side. It’s easy to change the knives by swinging the knife frame to the side. Each knife can be unlocked by the central knife release, and removed individually at each point in the frame.

Reliability thanks to Trimatic

Each knife is protected separately by a spring with the unique impact guard system. If the rotor pushes a foreign object onto the knife, the spring buckles and immediately reduces the force onto the knife. This tension automatically returns the knife to its operating position after the foreign body has passed through. The innovative, spring-based trigger system protects the knives and rotor, and guarantees constant functionality even in the harshest of operating conditions.

Construction

The similarity of the front side of Fendt Tigo with a trough has a very specific reason. The operator always has a perfect view in the loading space through the forward sloping body design. With a loading capacity of 31 m³ to 50 m³ (DIN) you can transport your harvested crop quickly and efficiently. At 50 m³ (DIN), the Tigo MR 100 Profi really plays out this strength, as a loading wagon specially designed for hay.

The first component of VarioFill is the bulkhead

More compact, easier, more manoeuvrable and shorter by at least 1 meter than other loading wagons in its class. With its 80° pivoting multi-functional bulkhead, the Fendt Tigo is one of a kind when it comes to loading. Using the space above the loading unit creates 6m³ more capacity while the vehicle length is still short. The completely closed frame of the bulkhead offers maximum stability in turn. The combination of weight saving and compact size make Fendt Tigo the payload champion. Combined with the Fendt tractor, it becomes an unbeatable team. You can profit from better road holding during transport through ideal weight distribution and optimum tongue weight.

The second component of VarioFill is the automatic loading

Always exercise the right pressure with the Fendt Tigo. With the bulkhead acting both as a loading and feeding wall, plus integrated automatic loading and unloading system, every cubic metre of the loading volume is put to best use. Adjust the 2-step automatic loading and continuously adjust the compression pressure of the feed from the terminal. The pre-compacting pressure can be customised optimum to the feed structure with this unique system. Whether it is higher pressure for a maximum loaded wagon or lower pressure to avoid crumbling losses in hay – as soon as the selected compression pressure is reached in the pressure sensor of the hydraulic cylinder, the scraper floor automatically sets itself in motion. If the complete loading space is filled, the bulkhead moves gradually forward.

The third component of VarioFill is the automatic unloading

Manual removal of feed residues at the end of the day is not required. The VarioFill makes the unloading a relaxed affair. The unloading process starts with pressing a button. The trunk lid is opened and then the scraper floor and the bulkhead start simultaneously. The multifunctional wall gently pushes the feed stock through the declining movement and reduces the load

of the scraper floor chains. The bulkhead presses the last feed wedge actively to the scraper floor through the arching position arising in the end position and ensures

that the vehicle is properly emptied.